Risograph Swatch Chart

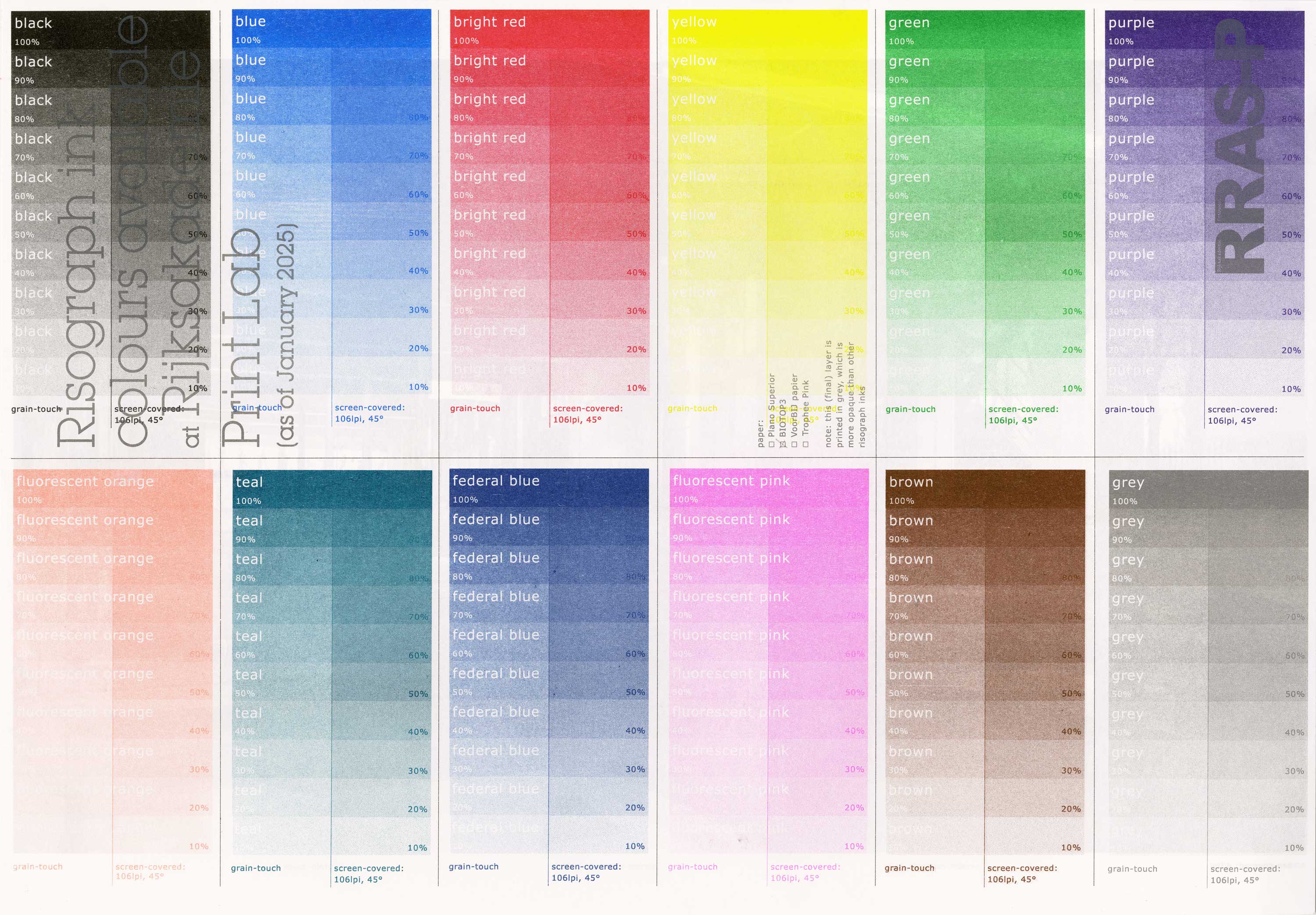

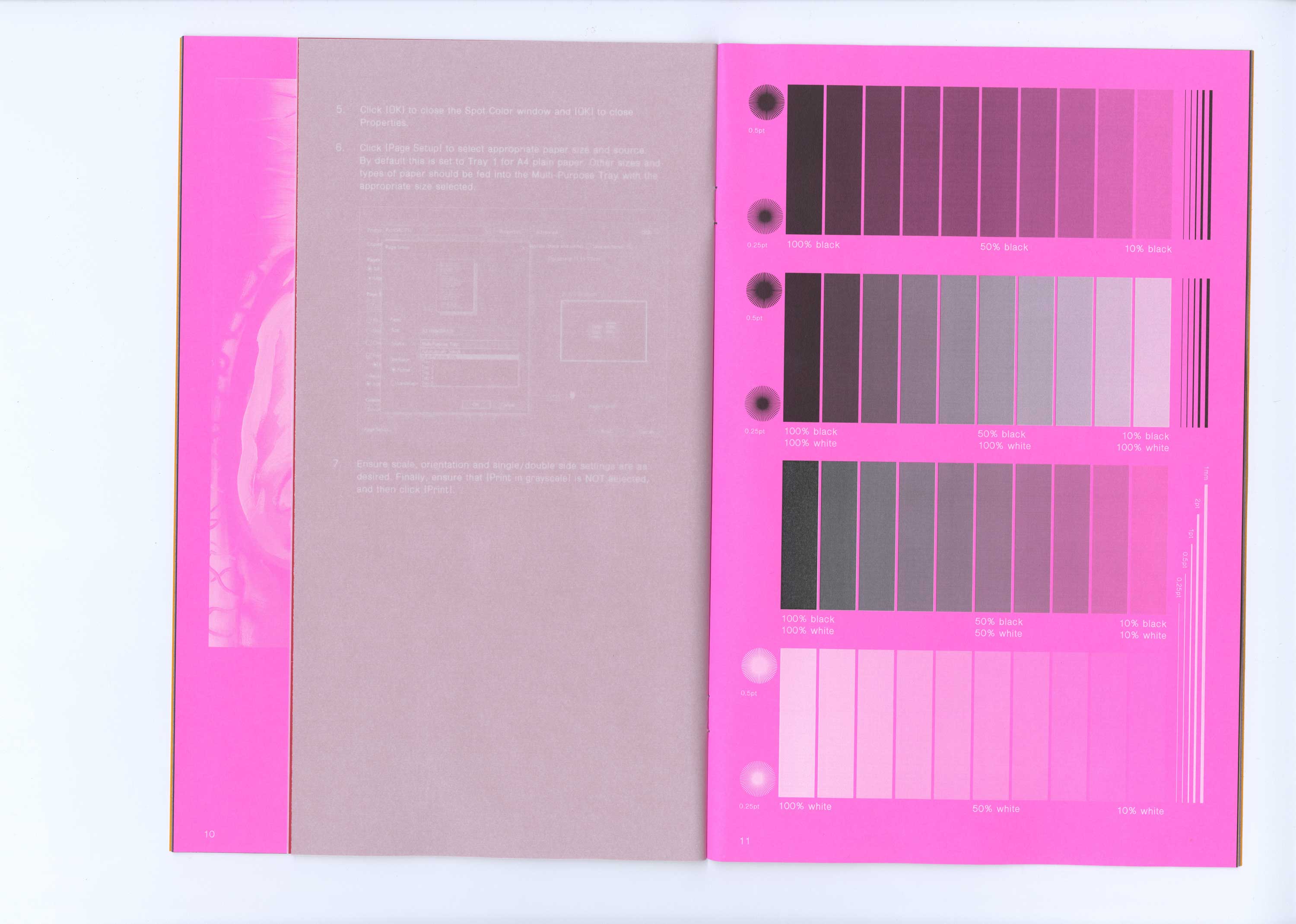

A risograph is a digital stencil printing machine that is useful for producing prints and publications in small–medium size editions (i.e. between 50–500 copies). It is often described as functioning like a cross between a photocopier and screen-printing, because it is fast and automated (similar to a copier), but prints in single ink layers through a stencil (similar to screen-printing). The Rijksakademie print workshop has a Risograph MH9350 which has two drums (meaning it can print two ink layers in a single pass) and prints A3 size with 12 possible ink colours. This A3 chart displays swatches of these 12 inks, each across a tone ladder in 10% increments. The reverse-side of the chart shows different halftoning options.

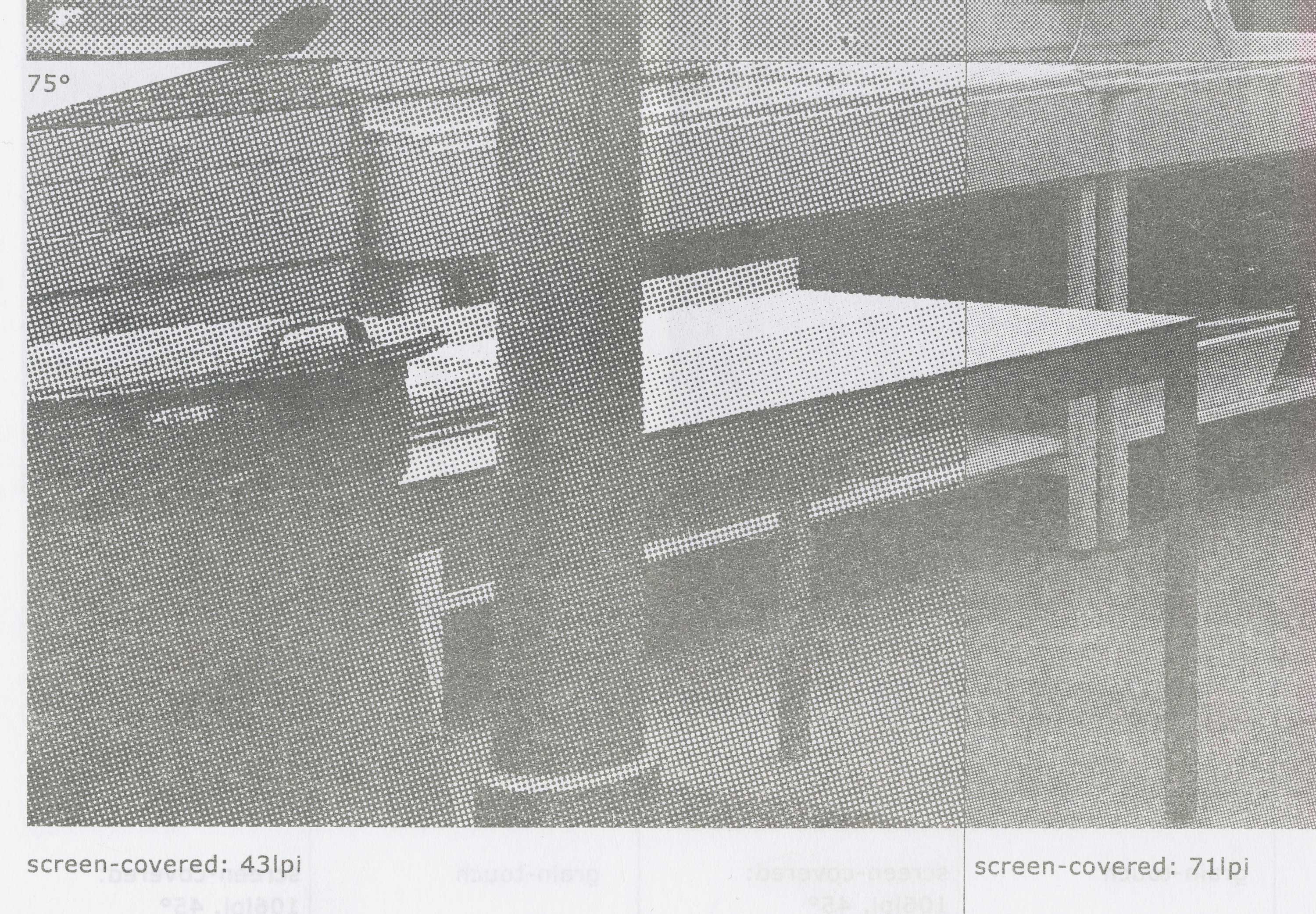

The risograph has a RIP (Raster Image Processor) that can halftone images in two different ways: screen-covered and grain-touch. Screen-covered (also known as "AM") is a grid composed of circular dots which vary in size depending on how dark the image is. Grain-touch (also known as "FM" or stocastic) is a random pattern, whereby darker areas of an image are more dense in noise.

For more information about how the risograph works, check out the following links: Stencil.wiki; Risotto Studio guides; Exploriso

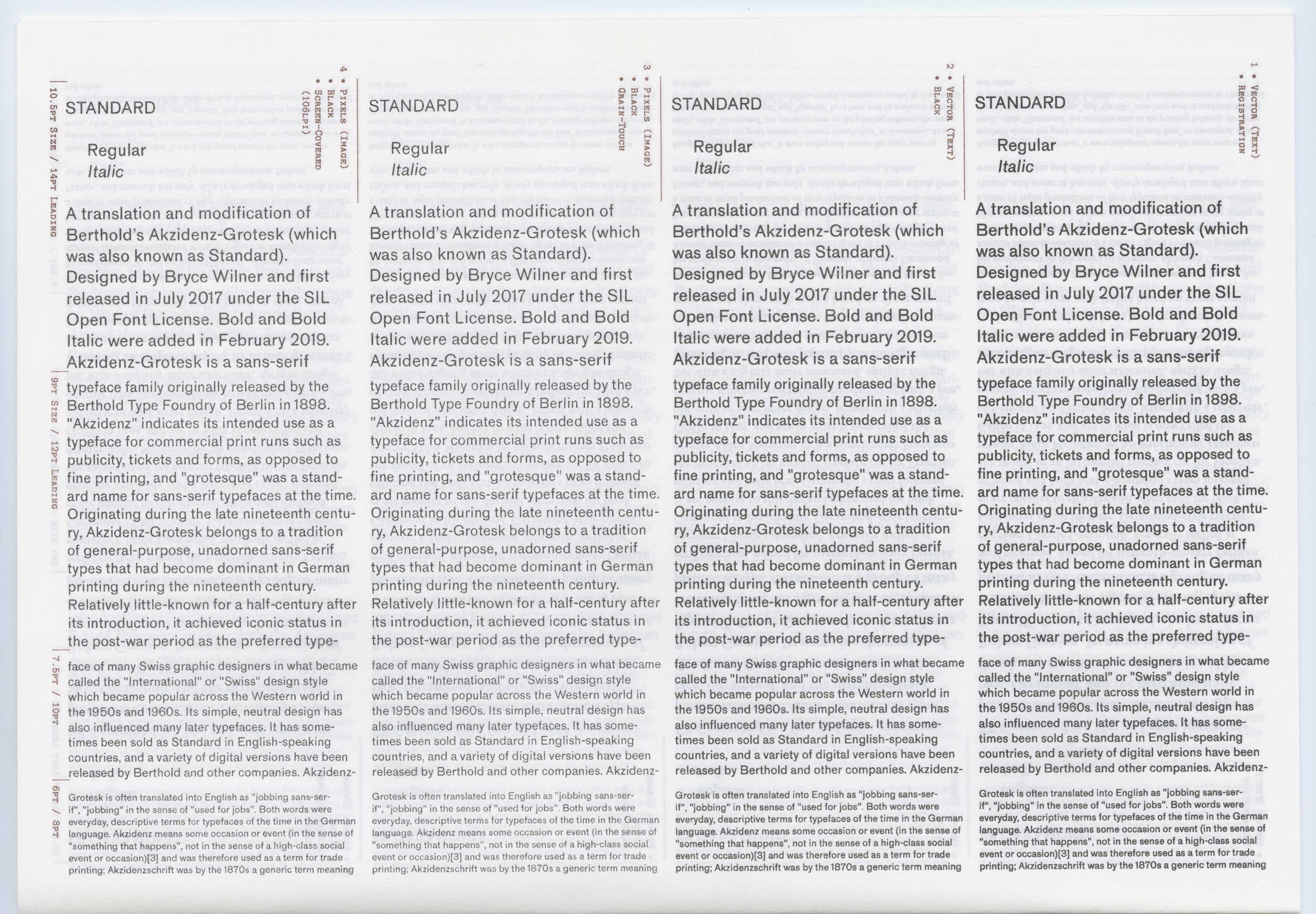

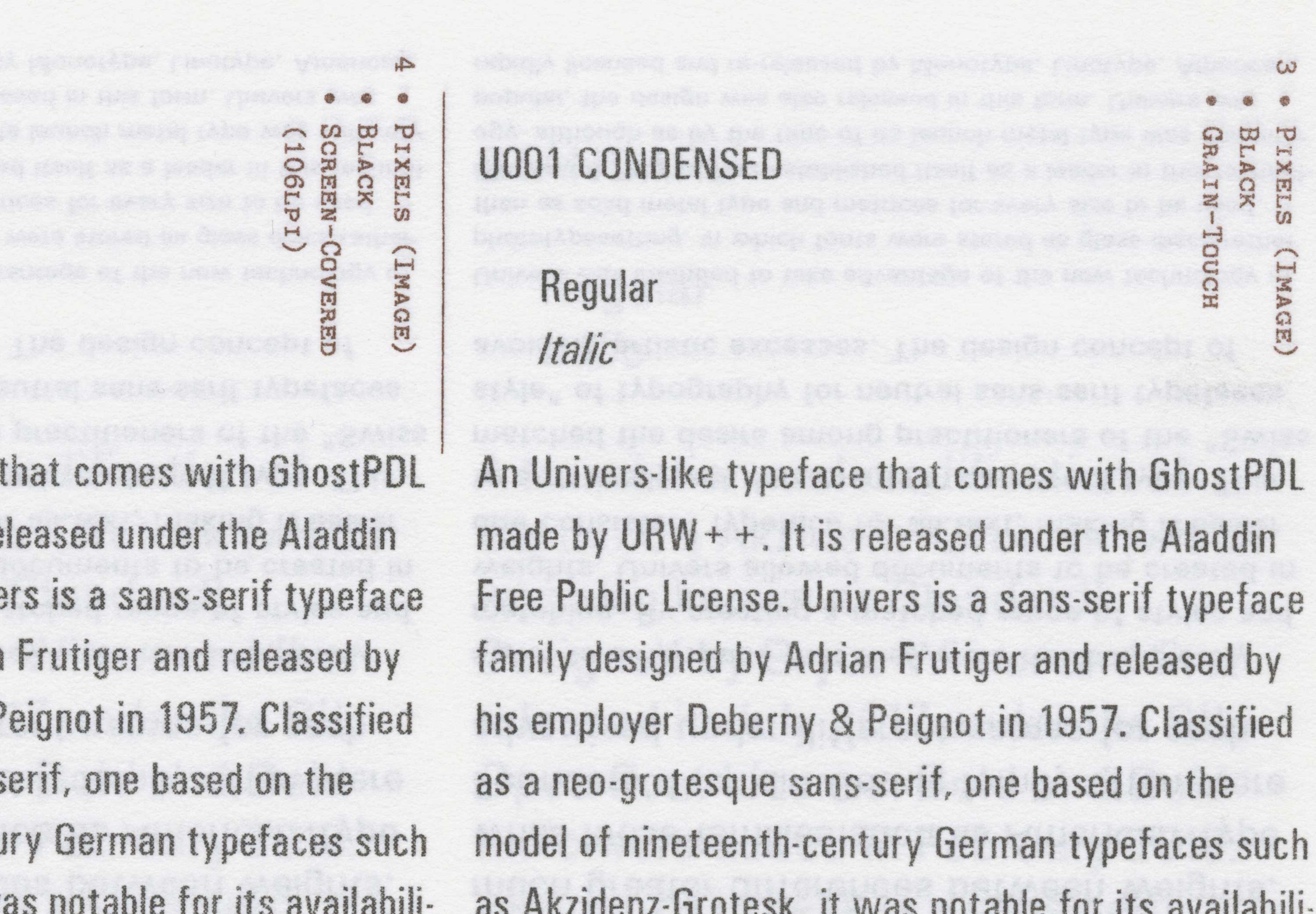

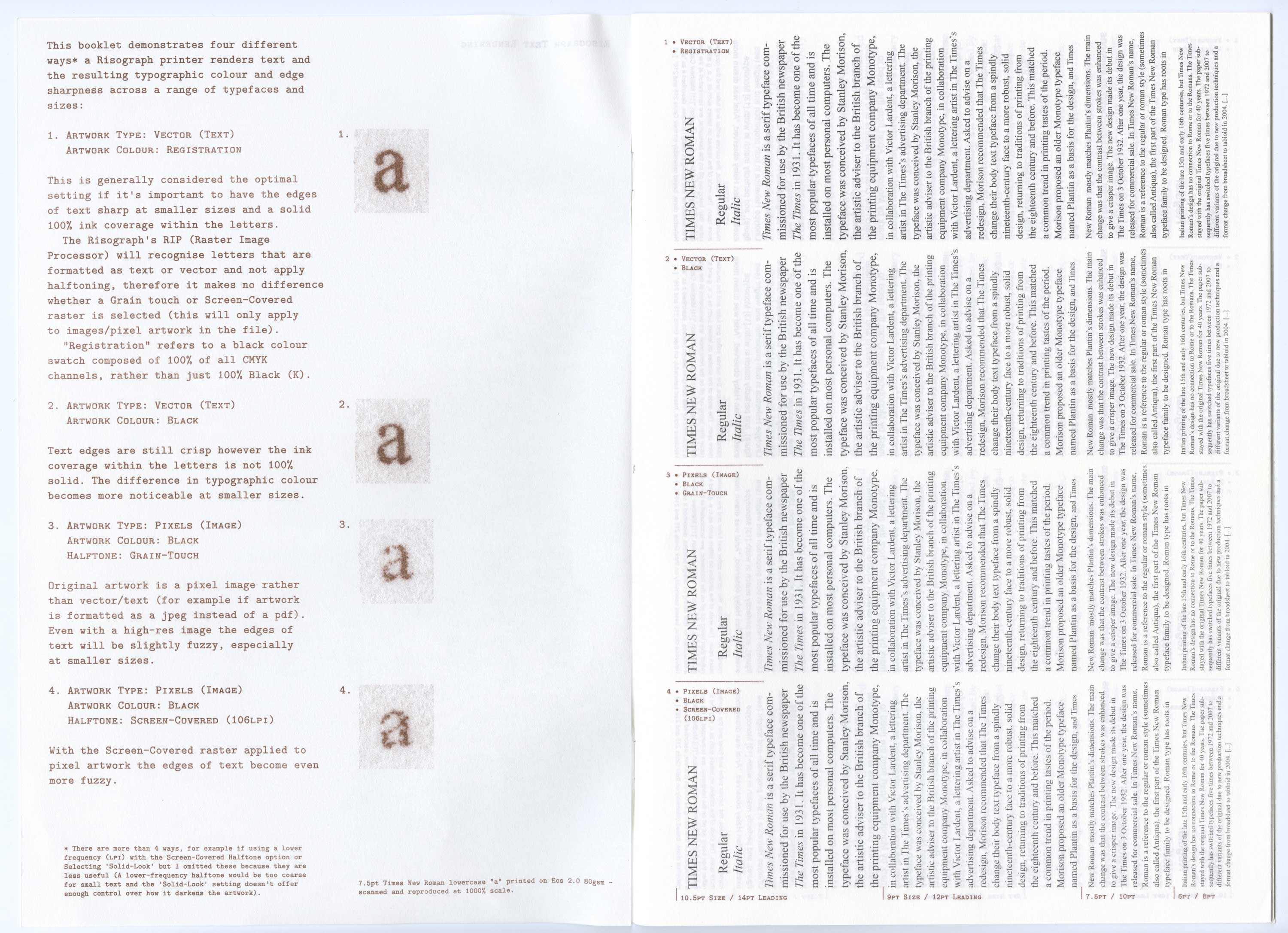

Risograph Text Rendering

A guide to the different ways text can be rendered by a risograph, depending on artwork type (whether vector/text or image), artwork colour (whether black or registration) and halftoning choice (screen-covered or grain touch). These options are demonstrated across 16 typefaces and across 4 body-text sizes ranging from 10.5pt to 6pt. A print-ready pdf can be download here and a working file is coming soon.

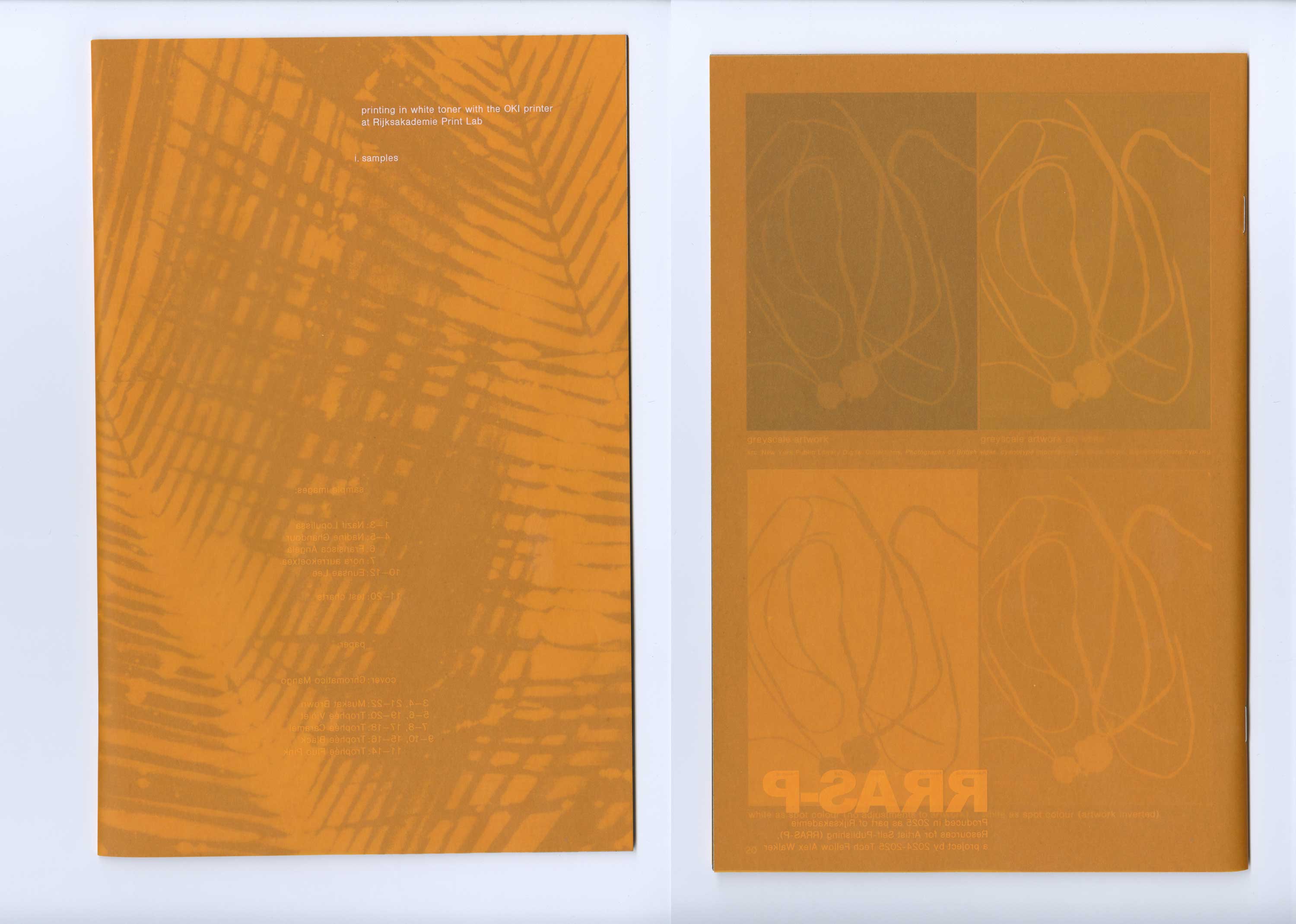

OKI white toner printing

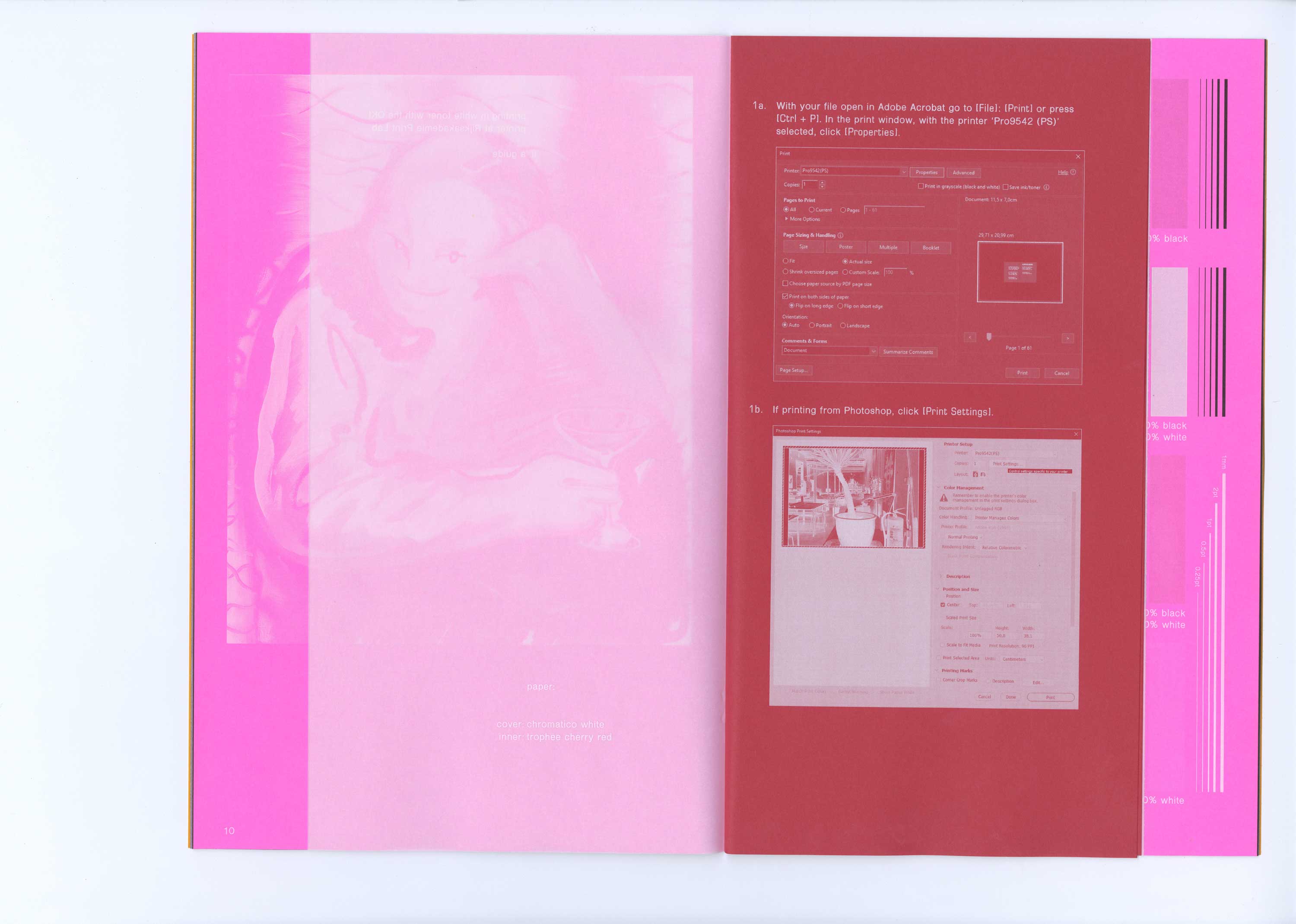

The OKI Pro9542 is a toner-based (AKA laser or xerox) printer. It's commonly used to print on A4 and A3 sheets but it can print up to a maximum width of 320mm and a maximum length of 1500mm.

It functions the same as a typical office laser printer: printing both black and full-colour, in a way that is fast and cheap making it ideal for producing zines. Like all toner-based methods, it produces a sharp print which appears to sit on top of the paper rather than bleeding into the papers fibres (as you would get with inkjet, offset or risograph), and you will notice a slight sheen across printed areas of the page.

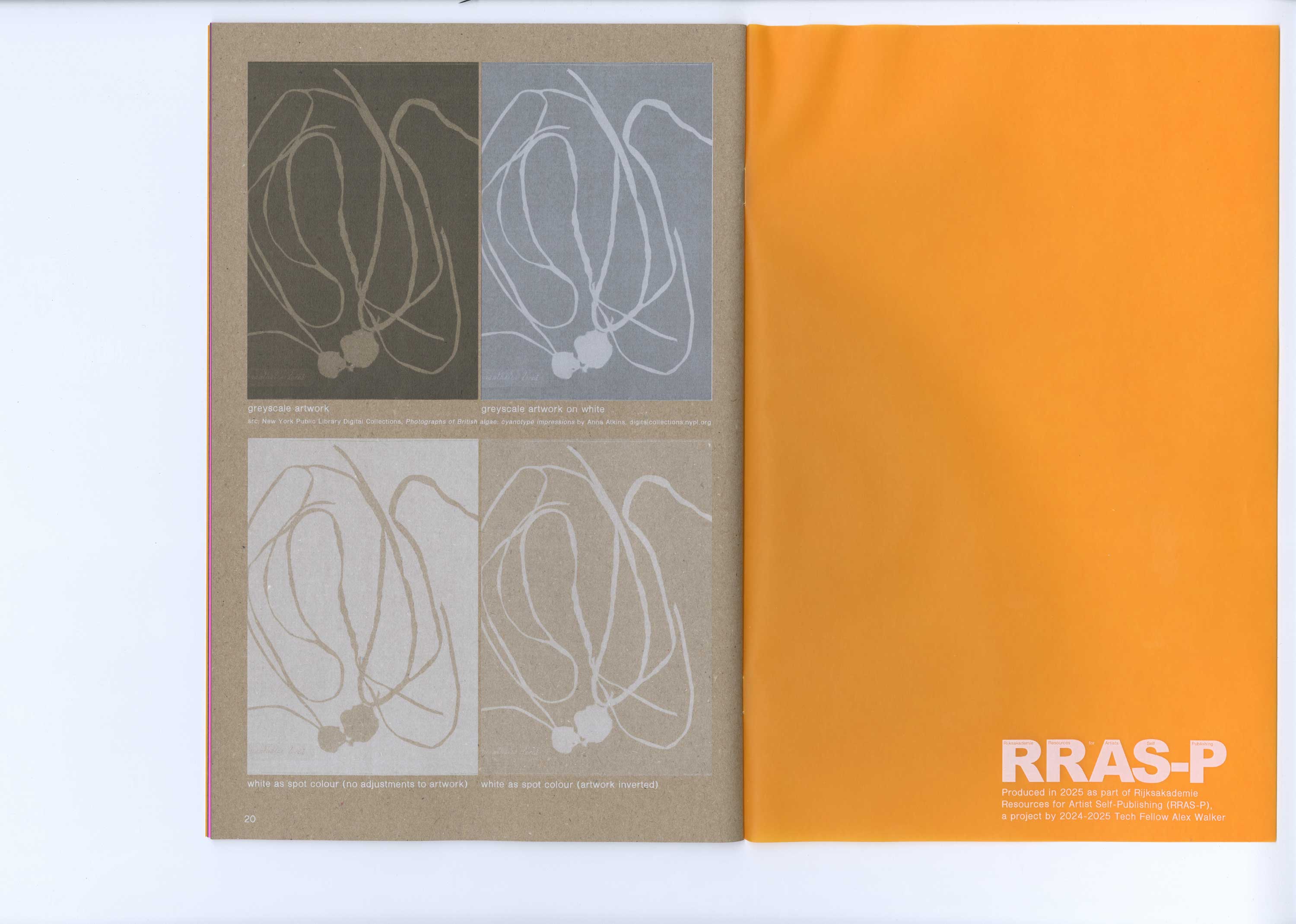

The most unique feature of this printer is the use of white toner. This can be used as a single spot-colour, or combined with black or CMYK in such a way that the white is used as a base layer to create a more opaque and vibrant print when used on a coloured or transparent stock. The guide and sample booklet I have produced shows examples of white as a single spot colour across a range of coloured papers, as well as a technical sheet showing white and black combined to show greyscales. A PDF of the guide booklet can be downloaded here.

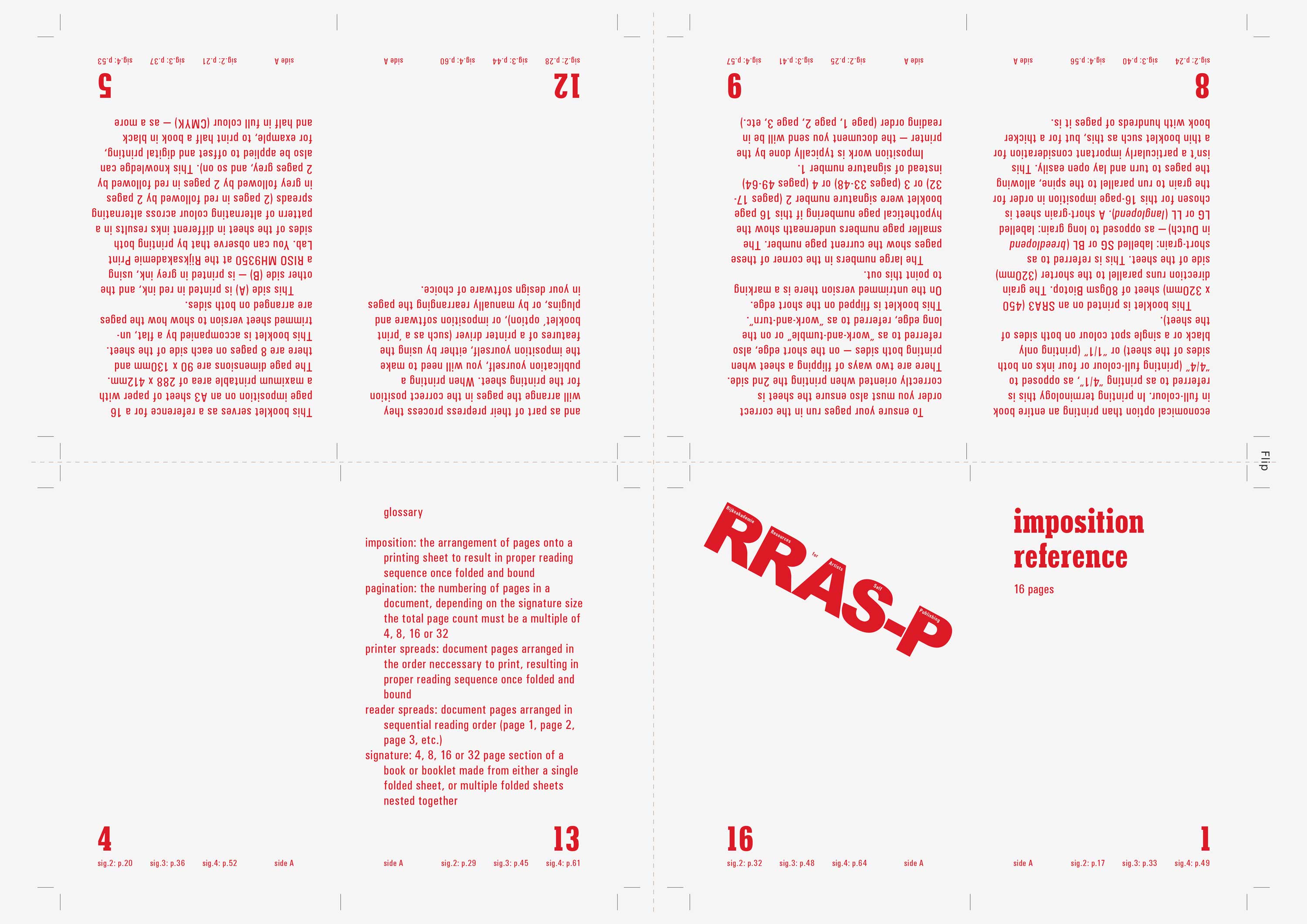

16 page imposition reference

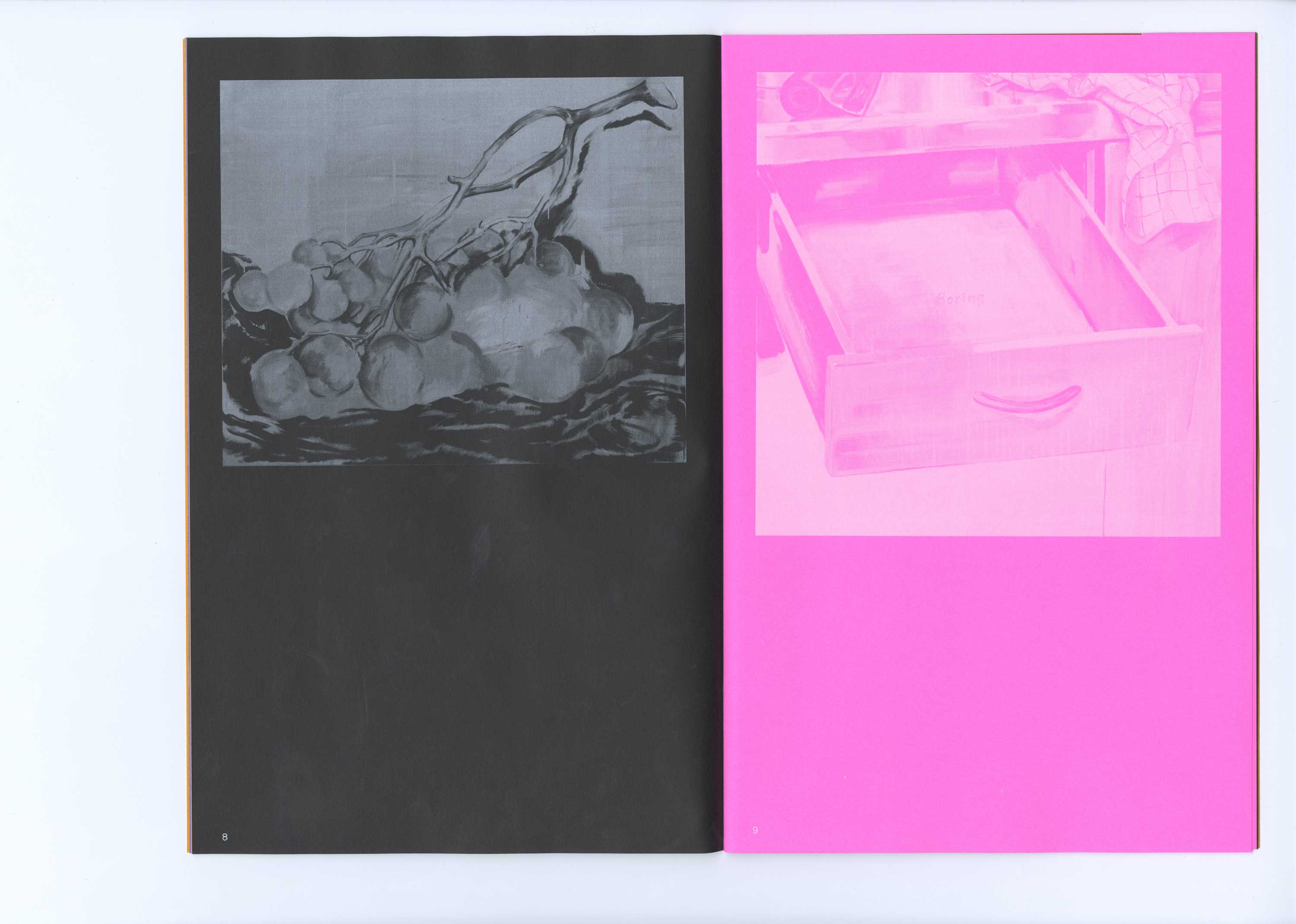

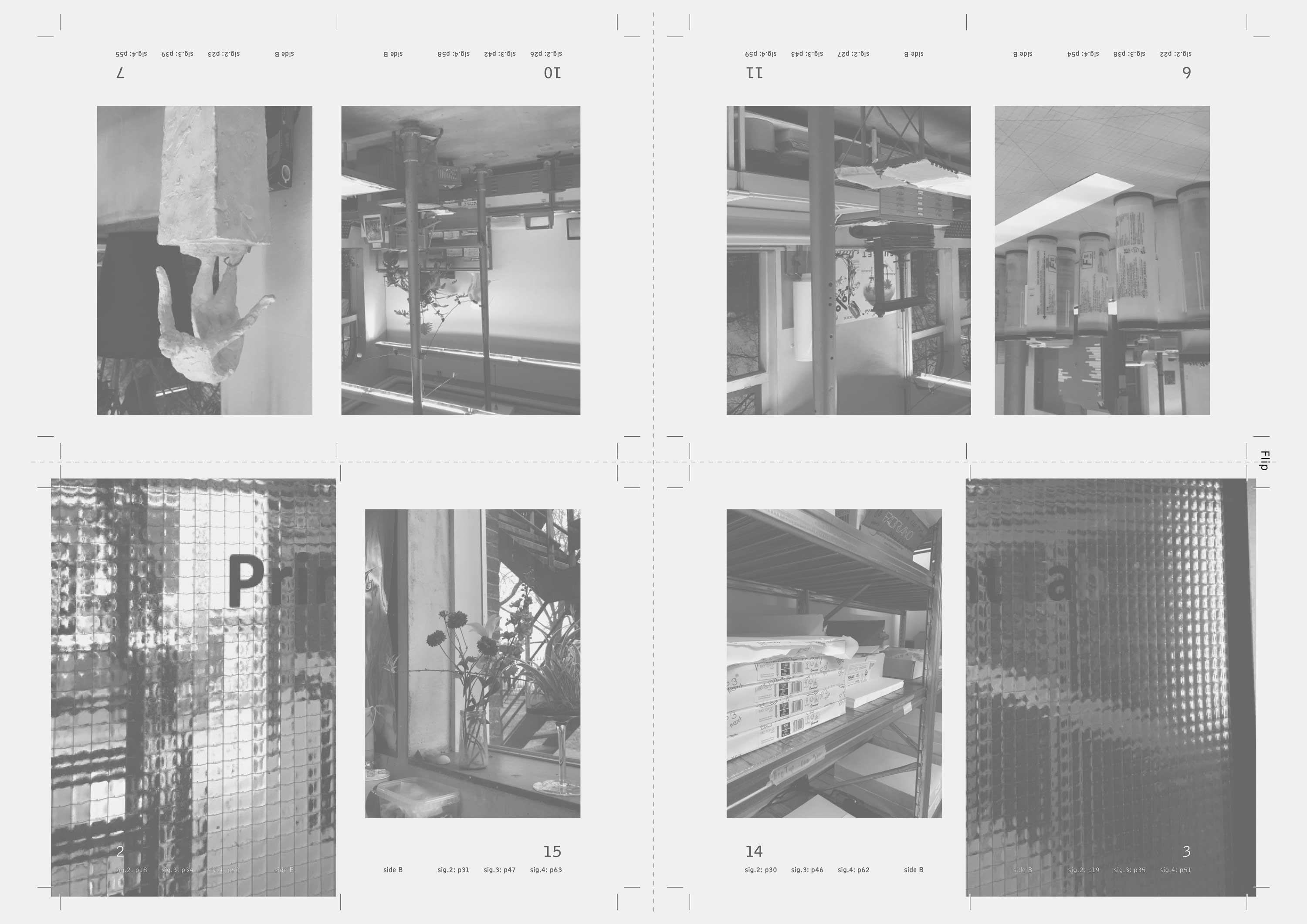

This booklet serves as a reference for a 16 page imposition on an A3 sheet of paper with a maximum printable area of 288 x 412mm. The page dimensions are 90 x 130mm and there are 8 pages on each side of the sheet. This booklet is accompanied by a flat, un- trimmed sheet version to show how the pages are arranged on both sides.

This side (A) is printed in red ink, and the other side (B) — is printed in grey ink, using a RISO MH9350 at the Rijksakademie Print Lab. You can observe that by printing both sides of the sheet in different inks results in a pattern of alternating colour across alternating spreads (2 pages in red followed by 2 pages in grey followed by 2 pages in red followed by 2 pages grey, and so on). This knowledge can also be applied to offset and digital printing, for example, to print half a book in black and half in full colour (CMYK) — as a more economical option than printing an entire book in full-colour. In printing terminology this is referred to as printing “4/1”, as opposed to “4/4” (printing full-colour or four inks on both sides of the sheet) or “1/1” (printing only black or a single spot colour on both sides of the sheet). A PDF can be downloaded here.

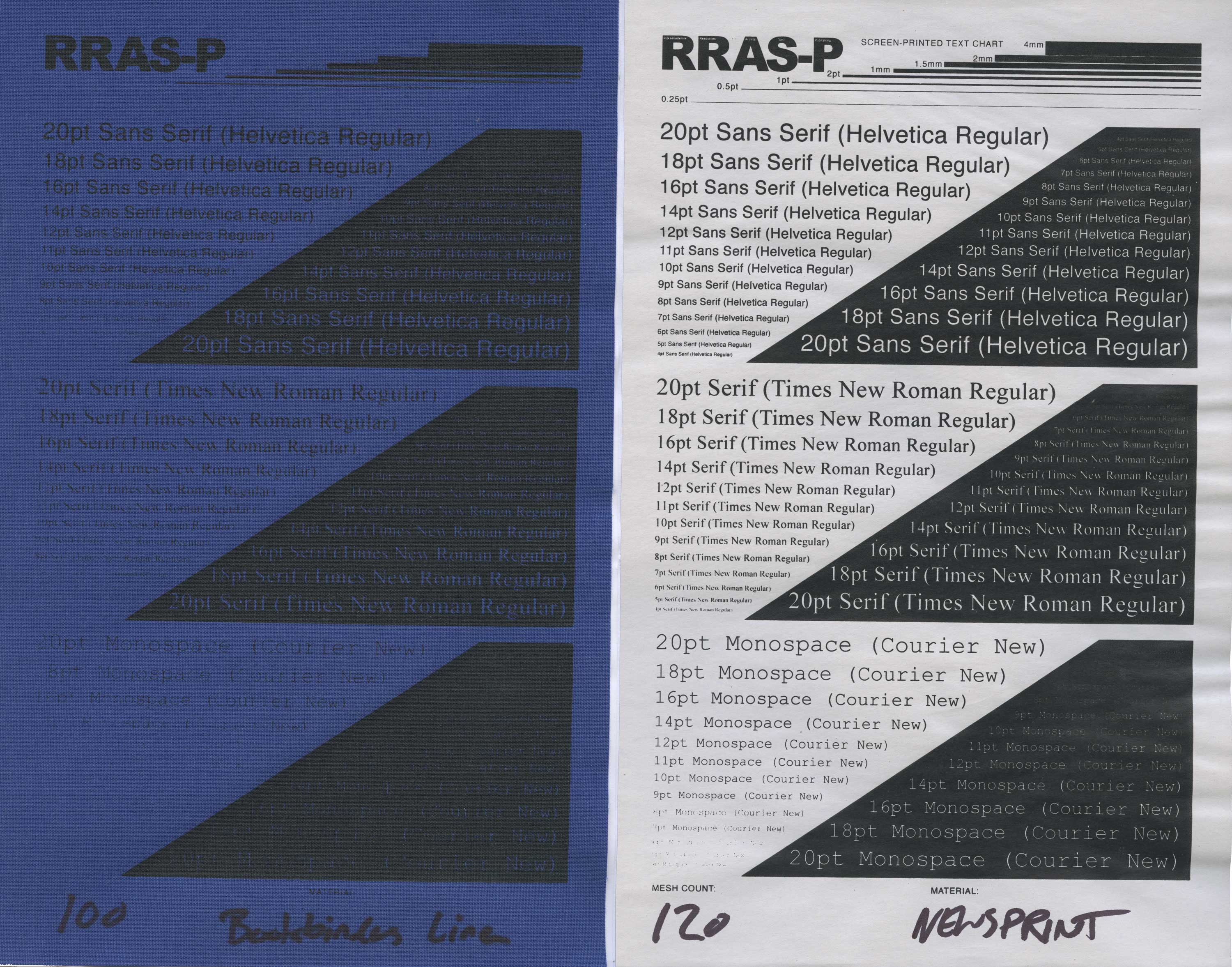

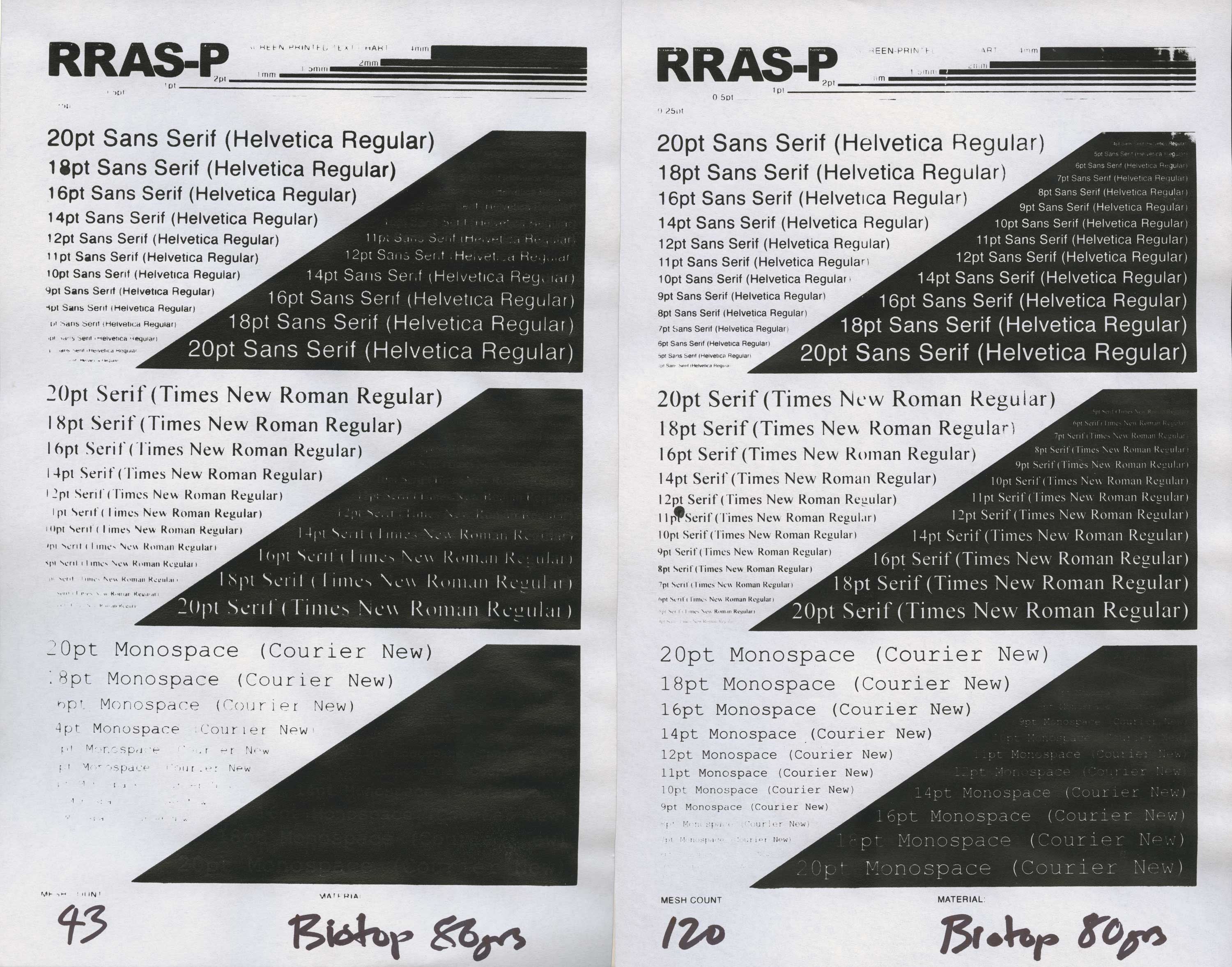

Screen-printed text chart

A text size chart screen-printed on a variety of different papers, board and bookbinders linen. Screens with three different mesh counts were used: 43, 100 and 120. A low mesh count (43) is a coarse mesh, primarily used for printing on textiles whilst a higher mesh count (100+) is used on paper and allows for finer detail to be produced. Whilst screenprinting is not a particularly efficient way to print pages of text for a publication, it is commonly used for book covers when unusual inks or cover material are required.